LED Lighting For Manufacturers

Helping Keep Employees Safer On The Factory Floor & Improving Productivity.

Contact Us Today To Discuss How Philips LED Lighting Could Improve Your Factory Environment

Lighting can account for up to 80% of a factory's energy bill, conventional batten lighting often fails and requires constant maintenance. Long lasting LED lighting from Philips can have an enormous impact on your bottom line, reducing the operational costs through reduced downtime and lower energy consumption while keeping your employees safer on the factory floor, and improving productivity.

Reduce Costs

- Lower energy consumption with cost-effective LED lighting and controls.

- Cut capital expenditure by using light as a service (LaaS) or circular lighting.

- Plan outages and maintenance to reduce disruption and downtime.

Optimise Operations

- Increase employee productivity and optimise labour costs by enhancing working conditions.

- Improve customer loyalty through improved manufacturing performance.

- Future-proof the work floorwith easy re-zoning, without changing the lighting fixtures.

Enhance Health & Safety

- Comply with national and international safety standards

- Create a safe work environment by ensuring a well-lit work floor

- Promote employee well being with high-quality LED lighting.

Improve Sustainability

- Lower carbon footprint by reducing energy consumption

- Minimise environmental impact with improved efficiency, fewer mistakes and less waste.

- Promote employee well being with high-quality LED lighting.

Smarter Warehouse Lighting

A flexible and intelligent energy saving system

Lighting With Benefits Beyond Belief

Philips offers the latest high-efficiency lighting with benefits that could make a significant impact on your company whilst helping to create a cleaner environment at the same time.

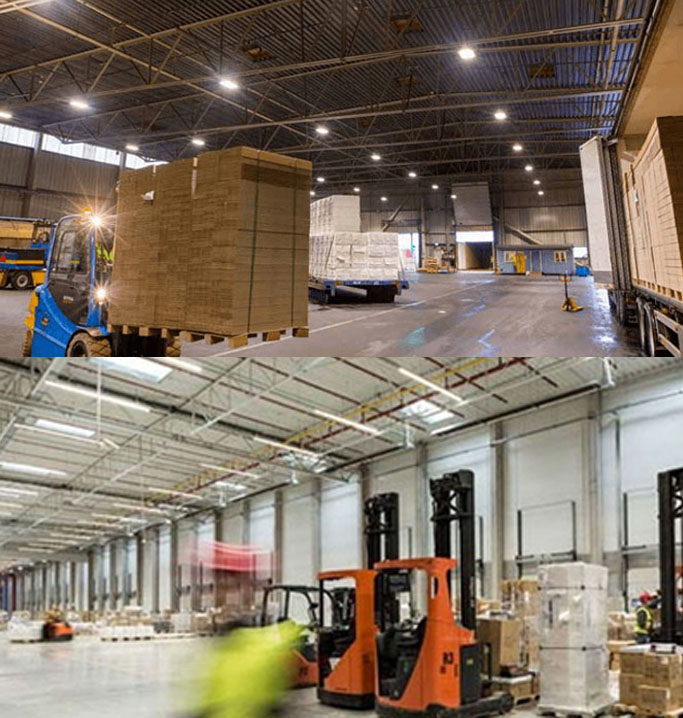

Philips led lighting used in warehouses are a perfect solution. With a range of different lighting fixtures available to you from hanging fixtures to fixed lighting Philips offer it all, working to accommodate each customer's specific needs and making it an ideal investment for any business looking to transform their warehouse into a visionary by upgrading to the very best lighting fixtures on the market. Over the past decade, the demand for led lighting has become increasingly popular, with more and more businesses looking to enhance their lighting systems for ultimate reliability and ease throughout the lifespan of their lighting fixtures. LED’s put the trust back into lighting giving customers a sense of confidence knowing they're being provided with top of the range LED lights that can't be beaten at insanely generous prices.

As technology becomes more advanced it's important your workplace is kept up to date with clean and aesthetically pleasing fixtures that never fail to impress. We often receive phone calls from customers unhappy with their old lighting fixtures because they lasted no more than a few years before things started to go wrong and needed constant maintenance to fix. LED’s don’t have this problem because they're designed to exceed all the expectations of lighting fixtures and provide flexibility and sustainability over a long period of time.

How We Calculate Your New Lighting Project.

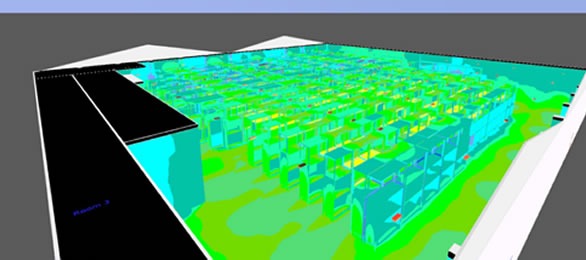

With the rising cost of energy and ever increasing demand for high efficiency lighting, the LED market is rapidly expanding. LED's promise high efficiency, but the cost is still higher than traditional lighting. So how can Empower Energy design team get more light out of an LED design to reduce the lights required ? Let’s take a look at how we design your new LED lighting: The Dialux software design tool draws from an extensive library of LED's, drivers and heat sinks to design your complete lighting system. Dialux software enables our in-house design team to perform real-time comparisons using 3D graphical visualisation.

We start the design by understanding your existing lighting and existing LUX levels and from this point we then need an understanding of what your requirements are within the areas we are designing. Usually this will have been ascertained from our site assessment and consultation.

So, for example if we design a manufacturing area, the required LUX could be between 700 and 1000 depending on Clients requirements. We start with our on-site technical survey to calculate the size of the area and height of the existing lighting and measure the lighting levels to understand the existing LUX levels. Our designers input the measurements and build the area. Once we have the full design built into the software, we then select the desired light output in lumens and the right luminaire and populate our 3D modelling software.

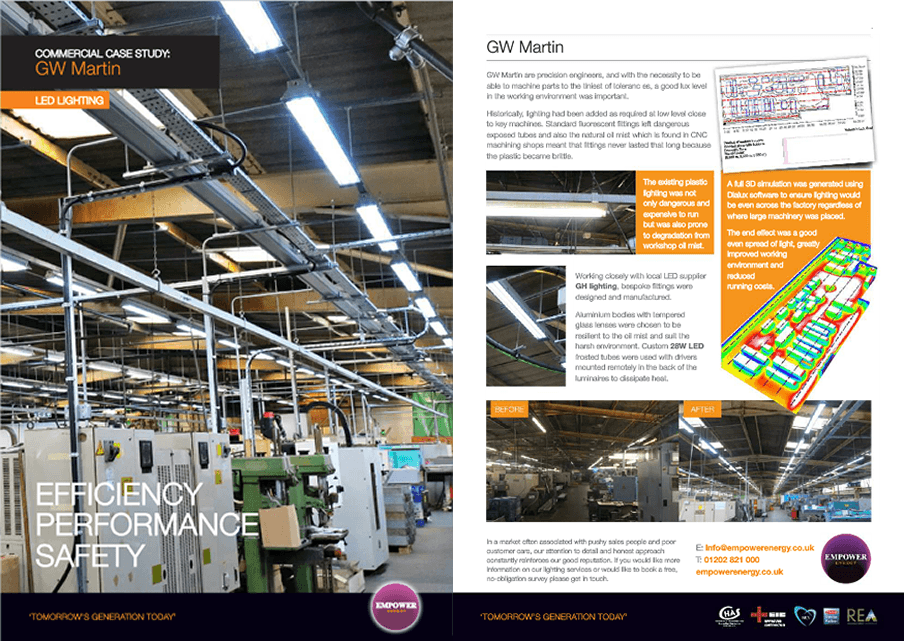

GW Martin

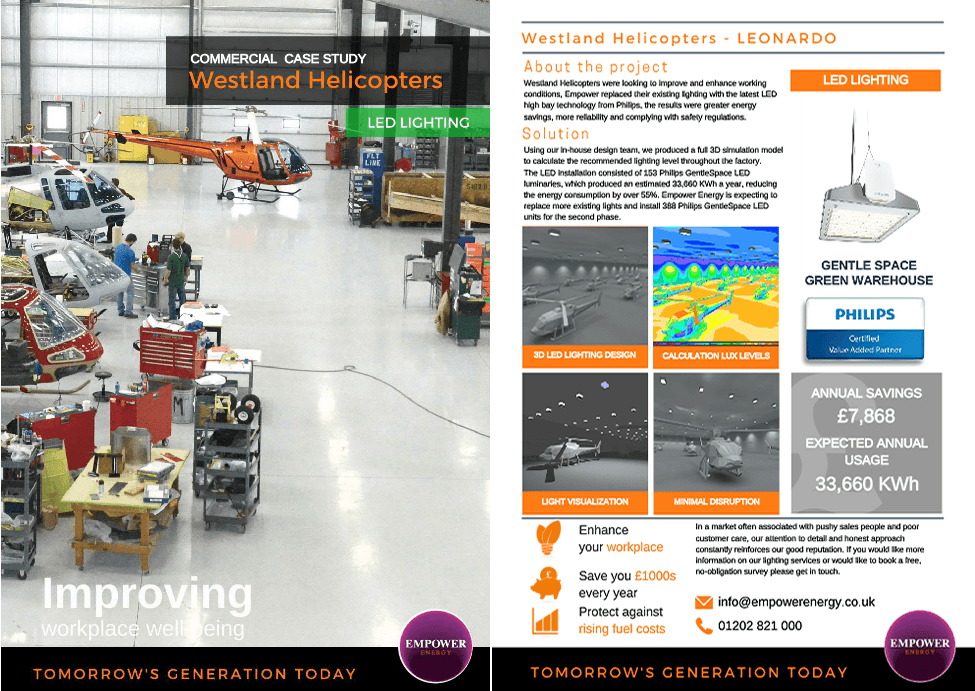

Westland Helicopters

Key Facts

Annual Savings £7,868Expected Annual Usage 33,660 KWh

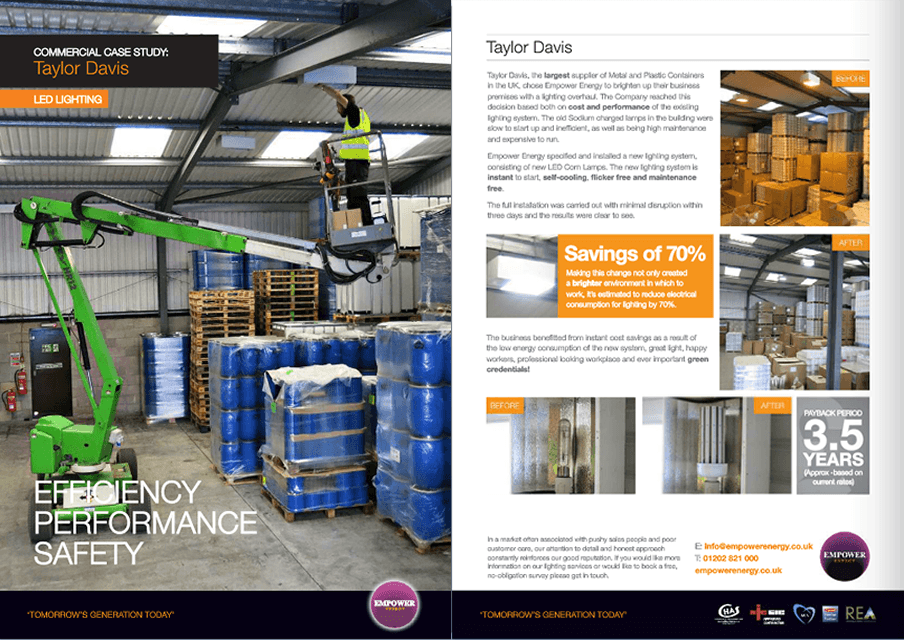

Taylor Davis

Key Facts

Savings 70%Payback 3.5 years

Presence detectors can be fitted and used to turn lighting on and off when required

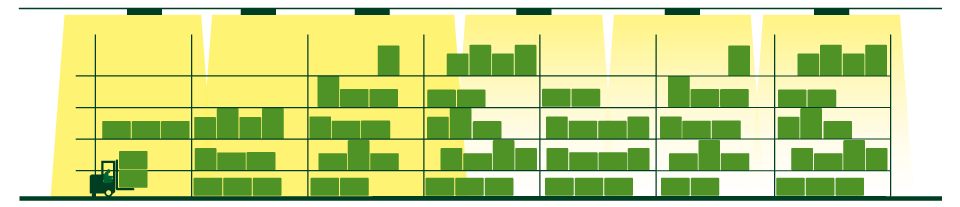

Control Your Warehouse

Using Coreline High-bay lighting with dali dimming, your warehouse can be divided into ‘zones’ or areas. Presence detectors, placed throughout each of the areas trigger full-output lighting when movement is detected in, or approaching that ‘zone’; ensuring people and vehicles can move around the warehouse safely. When a space is unoccupied, lighting dims to an energy-saving background lighting level.